HKUST Engineering Develops World’s First Sub-Zero Celsius Elastocaloric Green Freezer

Researchers at the School of Engineering of The Hong Kong University of Science and Technology (HKUST) have developed the world’s first Sub-Zero Celsius elastocaloric freezing device, capable of reaching temperatures as low as -12 ℃. This represents a significant milestone in expanding green solid-state elastocaloric refrigeration technology into the global freezing industry, offering a promising solution to combat climate change and accelerate low-carbon transformation of the global freezing market. The findings have recently been published in the international journal Nature, under the title “Sub-zero Celsius Elastocaloric Cooling via Low-transition-temperature Alloys”.

As global warming intensifies, the demand for freezing has been growing rapidly and accounts for a significant portion of global electricity consumption. Mainstream freezing based on vapor compression cooling technology relies on refrigerants with high global warming potential (GWP). As an eco-friendly alternative, solid-state cooling technology based on the elastocaloric effect of shape memory alloys (SMAs) has drawn substantial attention from both academia and industry due to its zero greenhouse gas emissions and high energy efficiency potential. The technology harnesses the latent heat from cyclic phase transition of shape memory alloys to provide cooling without greenhouse gas refrigerants, offering a promising path to decarbonize the freezing sector of cooling industry and to mitigate global emissions and climate change.

However, the existing elastocaloric devices have been limited to air conditioning scenario for room temperature applications, it is important to expand the technology into the freezing sector which has the same market size as the air-conditioning sector.

A research team led by Prof. SUN Qingping, Chair Professor from the Department of Mechanical and Aerospace Engineering at HKUST, has achieved a breakthrough in Sub-zero Celsius elastocaloric cooling. This advancement results from a synergistic combination of materials, heat transfer fluid and refrigeration structures. The features include:

(1) Super-elastic alloy: employing a binary low-transition-temperature nickel-titanium (NiTi) alloy with a high nickel content (51.2 at%) and lowering its austenite finish temperature (Af) to -20.8 ℃. This alloy maintains excellent super-elasticity and a substantial latent heat even at -20 ℃, with a peak adiabatic temperature change of 16.3 ℃ at 0 ℃ and a functional temperature window of 48.5 ℃.

(2) Freezing-resistant heat transfer fluid: using a 30 wt% aqueous calcium chloride solution as the working fluid. Its low freezing point ensures that it remains fluid in sub-zero operation, while its good wettability on the NiTi surface enhances heat exchange efficiency.

(3) Cascaded tubular architecture: the regenerator operates on a compression-based active Brayton cycle and consists of eight cascaded units, each containing three thin-walled NiTi tubes. This design offers a high surface area-to-volume ratio (8.68 mm-1) and withstands a compressive stress of 900MPa without buckling, as verified by X-ray computed tomography.

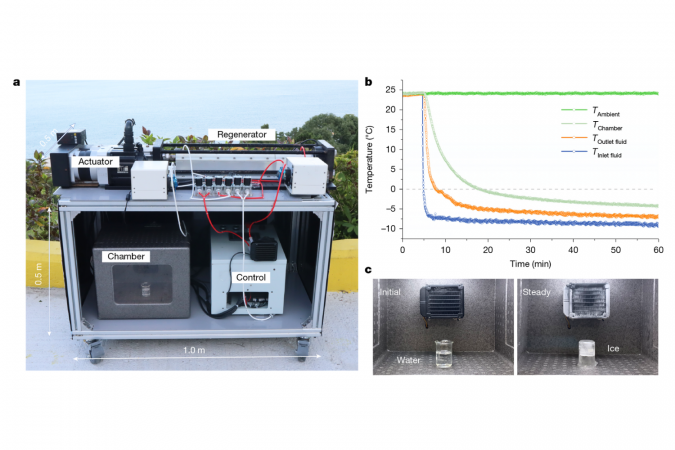

Operating at 1Hz, the desktop-scale device achieved a cold-source temperature of -12 ℃ from a room-temperature heat sink (24 ℃), establishing a temperature lift of 36 ℃. This is the first reported sub-zero Celsius performance in elastocaloric cooling. In a real-world demonstration, the system was integrated into a package measuring 1.0×0.5×0.5m3 and tested outdoors at temperature between 20 and 25 ℃. It successfully cooled an insulated chamber down to a stable -4 ℃ air temperature within 60 minutes and froze 20ml of distilled water into ice within 2 hours, validating its real-world freezing capability. The device demonstrated a specific cooling power of up to 1.43W g-1 under zero-temperature-lift conditions. In addition, the system’s coefficient of performance can reach 3.4 under ideal work-recovery assumption, highlighting its potential energy efficiency.

The work has significant impact on global decarbonization to battle the climate change. According to published data, global Hydrofluorocarbon (HFC) emissions are projected to exceed 1.2 gigatons of CO2 equivalent annually by 2025, with roughly 27% originating from sub-zero freezing applications. This translates to approximately 330 million tons of CO2 equivalent each year. The successful demonstration of sub-zero elastocaloric cooling provides a viable, emission-free alternative for these applications. Widespread adoption of this technology could, therefore, potentially mitigate around 330 million tons of CO2 equivalent emissions annually, contributing substantially to global climate goals.

The research team leader Prof. Sun Qingping stated, “This achievement demonstrates the potential for large-scale application of elastocaloric freezing technology. We are collaborating with industry to drive its commercialization. As global regulations on HFCs tighten, this zero-emission, energy-efficient freezing technology is poised to reshape the freezing sector of the refrigeration industry and provide a key technical solution for carbon neutrality. Looking ahead, we will focus on optimizing system efficiency, power density, and cost-effectiveness through advances in shape memory alloy materials, manufacturing, heat exchange design, and system integration and optimization to achieve larger cooling power and high energy efficiency.”

Prof. LU Mengqian, Director of the HKUST Otto Poon Center for Climate Resilience and Sustainability, where Prof. Sun and Prof. Zhou are affiliated members, said, “This groundbreaking advancement in elastocaloric freezing technology by our center’s members represents a significant step forward in our fight against climate change. By offering a zero-emission alternative for sub-zero applications, we are addressing the urgent need for sustainable freezing solutions. This achievement, published in prestigious journal Nature, has been phenomenal since the center’s establishment in July 2025. The work accelerates the center’s mission to deliver impactful strategies for climate resilience and sustainable development worldwide.”

This research was supported by the Strategic Topics Grant and General Research Fund of the Hong Kong Research Grants Council, Innovation and Technology Commission, Shenzhen-Hong Kong collaborative research initiatives.

This marks the second time the research team has published their work in Nature in less than a year. The previous publication was in February 2025, featuring their work on “Achieving kilowatt-scale elastocaloric cooling by a multi-cell architecture”.

About The Hong Kong University of Science and Technology

The Hong Kong University of Science and Technology (HKUST) (https://hkust.edu.hk/) is a world-class university known for its innovative education, research excellence, and impactful knowledge transfer. With a holistic and interdisciplinary pedagogy approach, HKUST was ranked 6th in the QS Asia University Rankings 2026, 3rd in the Times Higher Education’s Young University Rankings 2024, and 19th globally and 1st in Hong Kong in the Times Higher Education’s Impact Rankings 2025. Thirteen HKUST subjects were ranked among the world’s top 50 in the QS World University Rankings by Subject 2025, with “Data Science and Artificial Intelligence” coming in 17th worldwide and first in Hong Kong. Our graduates are highly competitive, consistently ranking among the world’s top 30 most sought-after employees. In terms of research and entrepreneurship, over 80% of our work was rated “internationally excellent” or “world leading” in the Research Assessment Exercise 2020 of the Hong Kong’s University Grants Committee. As of July 2025, HKUST members have founded over 1,900 active start-ups, including 10 Unicorns and 17 exits (IPO or M&A).

(This news was originally published by the HKUST Global Engagement and Communications Office here.)