Treasure Phase Diagram Map of Ferroelectric Properties: Can AI Really Unlock It in Seconds?

Researchers from the Hong Kong University of Science and Technology (HKUST) and Tongji University have developed FerroAI, a deep learning model that can produce phase diagrams for ferroelectric materials in just 20 seconds. Using FerroAI, the team discovered a novel ferroelectric material with an exceptionally high dielectric constant of 11,051, representing a significant advancement in AI-driven ferroelectric materials research. Their findings, published in the prestigious journal npj Computational Materials, offer an innovative approach to accelerating the design and discovery of functional materials.

This study, titled “FerroAI: a deep learning model for predicting phase diagrams of ferroelectric materials”, was jointly conducted by Prof. Sherry CHEN Xian (co-corresponding author), Associate Professor of the Department of Mechanical and Aerospace Engineering, HKUST, and Dr. ZHANG Chenbo (first author and co-corresponding author), Researcher of the School of Physics Science and Engineering and MOE Key Laboratory of Advanced Micro-Structured Materials, Tongji University, and 2019 PhD graduate of HKUST.

Ferroelectric materials are extensively utilized in sensors, memory devices, and energy harvesting applications due to their distinctive electrical properties. Their performance is critically dependent on crystal structures, whose evolution is typically characterized through composition–temperature phase diagrams. Conventional approaches to constructing these diagrams demand the synthesis of numerous samples, followed by extensive experimental testing and computational analysis. Such a process usually spans months or years. More efficient strategies for phase diagram construction and materials prediction underlie the horizon of basic research in the ferroelectric community.

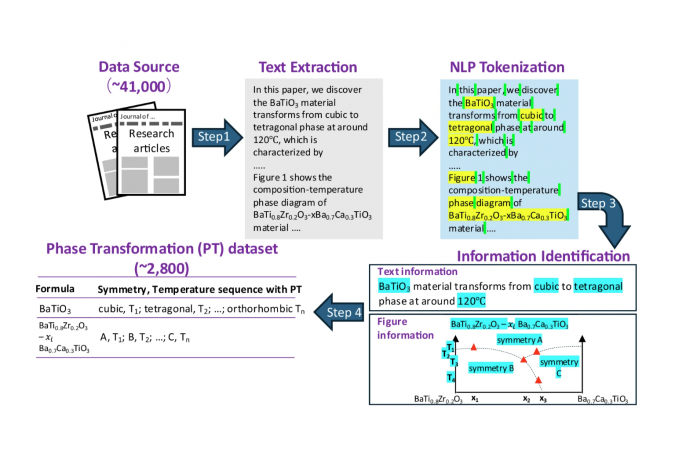

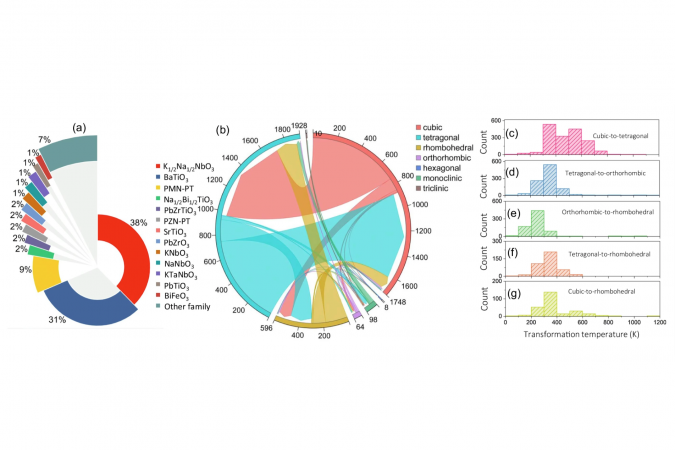

Previous machine learning approaches could predict phase transitions for specific material system but lacked sufficient generalization capability to accurately capture latent features across diverse material families. To address this limitation, the research team extracted data from over 40,000 published papers to construct a comprehensive phase-transformation database encompassing thousands of ferroelectric systems. Through advanced data augmentation techniques and intelligent parameter optimization strategies, the team developed and trained the deep learning model FerroAI. Experimental validation demonstrated that FerroAI achieves over 80% prediction accuracy across multiple crystal structures while providing insights into the critical roles of various dopant elements at specific lattice sites. Remarkably, tasks that traditionally require months of materials development work can now be completed by AI in just 20 seconds.

Prof. Chen said, “This study demonstrates the importance of high-quality datasets. In addition, the success of phase diagram prediction suggests that the research paradigm of materials science is being reshaped by AI, which promotes the rapid discovery of new functional materials.”

This achievement represents an important progress of the team in the field of intelligent materials. For the first time, a tight integration of phase transition prediction and experimental validation across material systems has been achieved. This showcases the huge potential of AI in accelerating both basic science and applied research.