HKUST Engineering Researchers Develop Innovative Method to Simplify Manufacturing Process of Cellular Ceramic

A study led by the School of Engineering of the Hong Kong University of Science and Technology (HKUST) has developed an innovative method that overcomes the limitations of traditional additive manufacturing (3D printing), significantly simplifying and accelerating the production of geometrically complex cellular ceramics. This groundbreaking approach has the potential to revolutionize the design and processing of multifarious ceramic materials, opening up new possibilities for new applications in energy, electronics, and biomedicine, including robotics, solar cells, sensors, battery electrodes, and bactericidal devices.

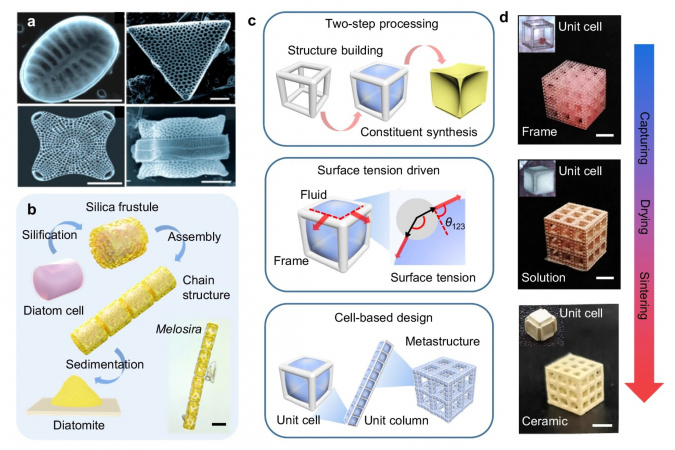

Cellular ceramics are widely used ceramic materials known for their stable performance, erosion resistance, and long service life. A research team led by Associate Professor YANG Zhengbao from the Department of Mechanical and Aerospace Engineering at HKUST designed a surface-tension-assisted two-step (STATS) processing strategy to fabricate cellular ceramics with programmed 3D cell-based configurations. This approach involves two key steps: (1) the preparation of cell-based organic lattices assisted by the additive manufacturing method to build the basic configurations, and (2) filling the precursor solution with the required constituent into the architected lattice.

One big challenge was controlling the liquid geometry. To address this, the team utilized surface tension, a natural phenomenon, to capture the precursor solution in architected cellular lattices. By leveraging the ability of surface tension to trap and pin fluids in prepared lattices, they successfully controlled the liquid geometry and managed to manufacture cellular ceramics with high precision.

The team further investigated the geometry parameters for the architected lattices assembled by unit cells and unit columns, both theoretically and experimentally, to guide the 3D fluid interface creation in arranged configurations. After drying and high-temperature sintering, the architected cellular ceramics were obtained. Using the new STATS approach, the ingredient synthesis was separated from architecture building, enabling the programmable manufacturing of cellular ceramics with various cell sizes, geometries, densities, meta-structures, and constituent elements. With high programmability, the method is applicable to both structural ceramics (e.g. Al2O3) and functional ceramics (e.g. TiO2, BiFeO3, BaTiO3).

To verify the superiority of the method, researchers also studied the piezoelectric performance of cellular piezoceramics. They found that the proposed approach could decrease the micropores and improve the local compactness in sintered cellular ceramics because of the significantly reduced organic component in the feedstock. This process benefits the manufacturing of globally porous and locally compact cellular piezoceramics, achieving a relatively high piezoelectric constant d33 (~ 200 pC N-1) even at a very high overall porosity (> 90%).

Prof. Yang revealed that the method was inspired by diatoms, which are algae commonly found in sediments or attached to solid substances in waters and serve directly and indirectly as food for many animals. Single-celled diatoms are distinctly characterized by their silica frustule, or external cell wall. Thanks to a genetically programmed biomineralization process, their frustules are constructed in highly precise structures that exhibit a variety of morphology, shape, geometry, pore distribution, and assembly.

“Our strategy overcomes the limitations of conventional manufacturing methods and enables the creation of programmable, geometrically complex ceramic architectures. This novel approach can help process numerous structural and functional cellular ceramics, contributing to applications involving filters, sensors, actuators, robotics, battery electrodes, solar cells, and bactericidal devices. Moreover, the philosophy of engineering fluid interface for solid fabrication also provides a new solution for combining interfacial processing with innovative manufacturing, enlightening the synergistic development of advanced design and intelligent materials,” Prof. Yang elaborated.

The study, titled “A Bioinspired Surface Tension-Driven Route Toward Programmed Cellular Ceramics”, was recently published in the first-rate multidisciplinary journal Nature Communications. Dr. HONG Ying, Dr. LIU Shiyuan, both former postdoctoral fellows at HKUST, and YANG Xiaodan, a PhD student under Prof. Yang’s supervision, were the first authors.

For media inquiries, please contact:

Celia Lee

Tel: 2358 8982 / Email: celialee@ust.hk

Dorothy Yip

Tel: 2358 5917 / Email: egkkyip@ust.hk

(This article was originally published on EurekAlert on September 10, 2024.)