HKUST Researchers Pioneer Breakthroughs in Catalytic Biomass Valorization to Advance Green Chemistry and Sustainable Engineering

A pioneering study led by Prof. Dan TSANG, Professor of the Department of Civil and Environmental Engineering at the Hong Kong University of Science and Technology (HKUST), has revealed a groundbreaking mechanism for selectively converting biomass into value-added chemicals, offering a low-carbon, oxidant-free path to green chemical production.

In situ hydroxyls unlock a new frontier in selective green catalysis

In a paradigm-shifting advance, the HKUST team unveiled a novel catalytic mechanism for biomass oxidation that eliminates the need for costly and hazardous oxidants. Traditionally, selective oxidation of biomass compounds has relied on chemical oxidants and the Mars-van Krevelen mechanism, which depends on lattice oxygen from metal oxides.

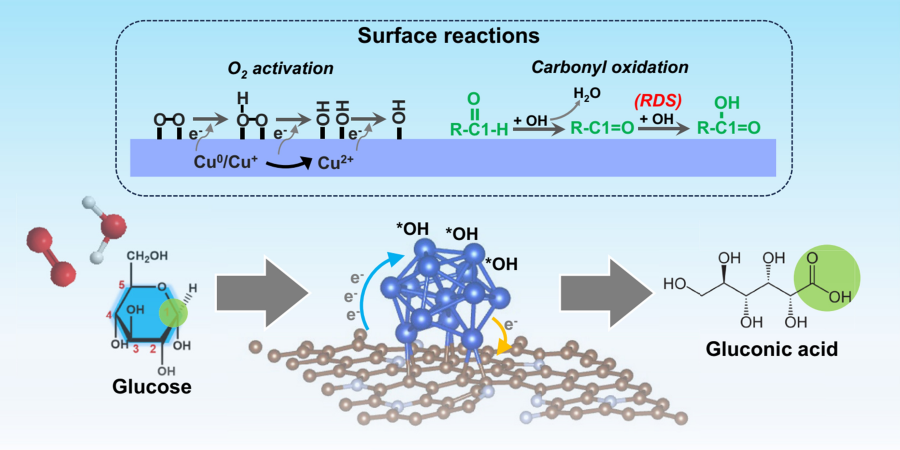

Instead, the researchers developed a nitrogen-doped carbon-supported copper catalyst that activates oxygen from ambient air and water, generating surface-confined hydroxyl radicals (*OHads). These reactive species selectively oxidize the C1=O group in glucose—transforming it into gluconic acid with over 90% selectivity, more than doubling the precision of conventional methods.

“This discovery is not only academically groundbreaking but practically transformative,” said Prof. Tsang. “We’ve shown that abundant and sustainable resources like air and water can drive highly selective biomass transformations, which is essential for building a green chemical industry.”

A green chemistry milestone: from glucose to carbon-neutral synthesis

Breaking away from the limitations of conventional redox pathways, the HKUST team introduced a new oxygen activation sequence—**O2 → OOH → OHads—to drive precision catalysis at the interface of low-valence copper on sustainable carbon support. This strategy enables site-specific oxidation of the aldehyde group in glucose, while preserving adjacent hydroxyl functionalities that are typically vulnerable to non-selective attack.

Key technical advances:

- Nitrogen-doped carbon modulates copper’s electronic structure and optimizes oxygen activation

- Interface-confined OHads ensures controlled and localized reactivity

- Eliminating chemical oxidants improves safety, reduces cost, and minimizes environmental impact

Toward industrial translation and global sustainability

Prof. Tsang’s research provides a scientific blueprint for scaling green technologies of biomass valorization from the lab to industrial applications. With robust mechanisms, scalable and sustainable materials, and reduced reliance on chemical oxidants, the research team advances multiple UN Sustainable Development Goals (SDGs), including clean energy, sustainable industry, and climate action.

“This is more than a scientific advancement—it’s a roadmap toward industrial-scale green chemistry and sustainable engineering,” Prof. Tsang added. “We envision integration with biorefining, clean energy, and environmental sectors to realize a truly circular bioeconomy. As part of this effort, we are working closely with the Hong Kong Environmental Protection Department to translate lab-scale R&D into field-scale biochar production and real-world applications—including the rational designs and emerging applications of biochar products in Hong Kong.”

Led by Prof. Tsang, the study titled “Revealing OH Species In Situ Generated on Low-Valence Cu Sites for Selective Carbonyl Oxidation”, published in Proceedings of the National Academy of Sciences (PNAS), presents a pioneering catalytic strategy for high-selectivity biomass valorization and sustainable chemical production. The research team includes Prof. Iris YU, Assistant Professor at the National University of Singapore, Prof. CAO Yang, Associate Professor at Nanjing Agricultural University, and Dr. ZHANG Qiaozhi, postdoctoral fellow at the National University of Singapore, all of whom completed their PhD training under Prof. Tsang’s supervision in recent years.