HKUST Researchers Pioneer Next-Generation Solutions for Carbon-Neutral and Intelligent Urban Construction

In a bold step toward reimagining urban development for a climate-resilient future, a research team led by Prof. Dan TSANG, Professor of the Department of Civil and Environmental Engineering at the Hong Kong University of Science and Technology (HKUST), has developed an innovation strategy that integrates intelligent 3D concrete printing (3DP) with scalable biochar-based carbon removal technologies. Together, these breakthroughs provide a cohesive roadmap for building sustainable cities that are not only smarter and more adaptive but also carbon-neutral by design.

Building the future: smart 3D concrete printing with a low-carbon footprint

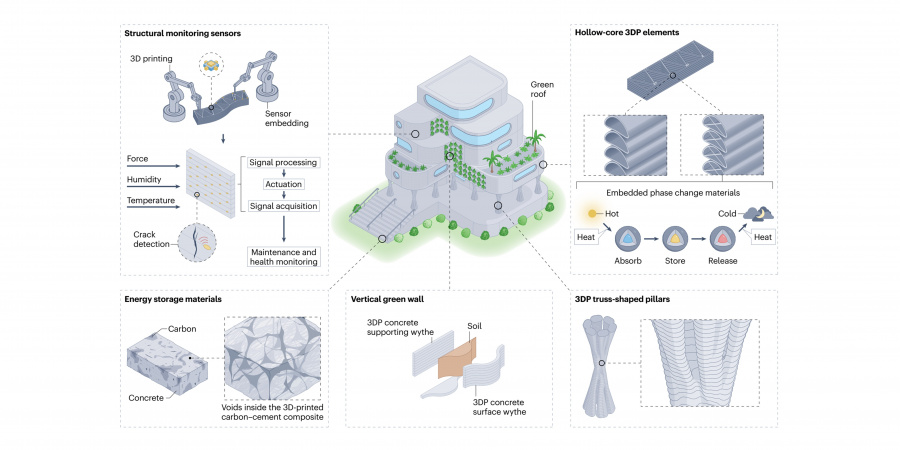

Concrete remains the most widely used construction material—and among the most polluting, responsible for over 8% of global CO2 emissions. The HKUST team envisions a shift from traditional, resource-intensive, and emissions-heavy construction to a future city built with formwork-free, topology-optimized 3D printed structures that drastically reduce material consumption and construction time while embedding intelligence into buildings themselves.

“Our research charts a path toward sustainable, automated construction that doesn’t just reduce emissions—it enhances the intelligence, adaptability, and livability of our future buildings,” said Prof. Tsang.

Using advanced manufacturing platforms, Prof. Tsang’s team has demonstrated:

- Material efficiency gains of up to 70% through geometry-driven designs

- Integrated smart features, including thermal insulation and sensor-enabled digital systems

- Flexible and automated fabrication, reducing labor reliance and construction waste generation on site

Unlocking urban carbon removal with scalable biochar solutions

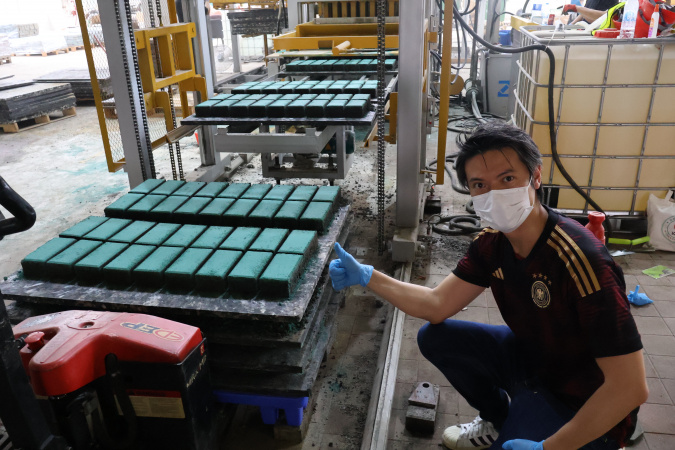

Central to this approach is the use of biochar, a carbon-rich material produced from diverse biomass waste through engineered pyrolysis. Rather than merely applying biochar in soil environment, HKUST researchers led by Prof. Tsang have innovated its scientific design and unconventional integration in the construction lifecycle—as a component of low-carbon concrete, a tool for carbon removal, and a medium for environmental improvement.

Already recognized by the Intergovernmental Panel on Climate Change (IPCC) as a scalable negative-emission solution, biochar offers unparalleled versatility: it improves soil health, supports urban greening, treats wastewater, improves degraded environment, and substitutes carbon-intensive construction materials.

“Biochar is more than a climate tool—it’s an indispensable bridge between sustainable waste management, green infrastructure, and circular economy,” said Prof. Tsang.

By embedding engineered biochar into cementitious materials, the HKUST team has created:

- Carbon-negative composites, capable of offsetting up to −720 kg CO2 per tonne of construction materials

- Multifunctional concrete with enhanced thermal insulation, acoustic performance, energy storage, and pollutant removal

- Production models supported by AI optimization to deploy engineered biochar in green infrastructure and curtail carbon emissions

With a projected global market value exceeding USD 3.3 billion, biochar’s role in carbon-neutral cities is commercially and technologically actionable. For instance, the HKUST team’s recent innovation, a biochar-based thermal insulating plaster that enhances energy efficiency and indoor comfort, was awarded a Gold Medal with Congratulations of the Jury – the highest level of recognition – at the 50th Geneva International Exhibition of Inventions, highlighting its practical potential in both residential and commercial settings.

HKUST at the forefront of climate-resilient urban innovation

Together, these advances form a comprehensive strategy to reshape cities from the ground up—fusing engineering innovation, digital manufacturing, and carbon sequestration into scalable urban solutions and climate-smart ecosystems.

“Our vision is to transform construction from a carbon-emission source into a climate solution,” said Prof. Tsang. “By uniting digital fabrication with resource circularity, we’re reinventing urban infrastructure that doesn’t just sustain—but restores.”

Led by Prof. Tsang, the seminal studies titled “3D Printing Technology in Concrete Construction”, published in Nature Reviews Clean Technology (Nature Portfolio), and “Scaling Biochar Solutions for Urban Carbon Dioxide Removal”, published in One Earth (Cell Press), advance an innovative vision for sustainable and digital construction. The HKUST team’s transformative research on decarbonization and green technologies was conducted in close collaboration with global experts, including Prof. Paulo MONTEIRO (University of California Berkeley), Prof. Roya MABOUDIAN (University of California Berkeley), Prof. Nemkumar BANTHIA (University of British Columbia), Prof. Josephine CARSTENSEN (Massachusetts Institute of Technology), etc.