Electronic Waste as Cost-effective Innovative Adsorbent to Clean Wastewater Novel Technology to Promote Recycling and Protect the Environment

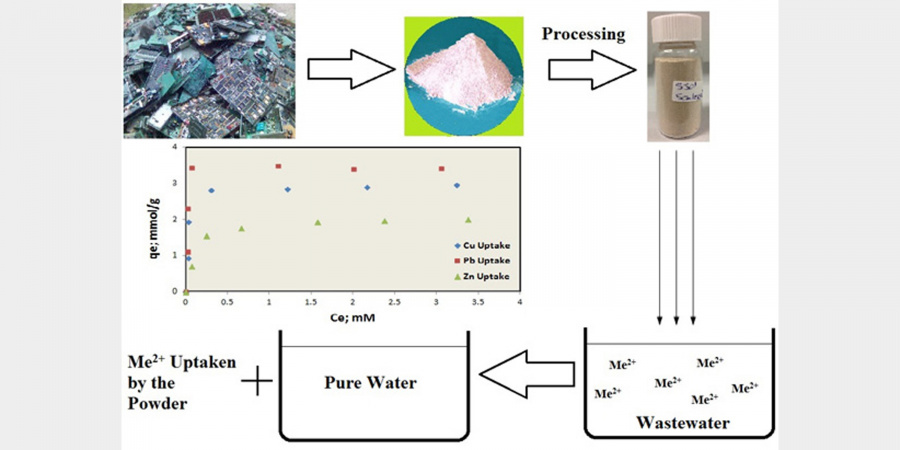

A team of researchers from the Department of Chemical and Biomolecular Engineering (CBME) have found a constructive new way to use electronic waste from discarded mobile phones, computers, other gadgets and electronic devices to clean up wastewater. In their paper entitled “Toxic Heavy Metal Capture Using a Novel Electronic Waste-Based Material — Mechanism, Modeling and Comparison” on Environmental Science & Technology, Prof Gordon McKay, Prof John Barford and Dr Pejman Hadi have shown that printed circuit boards (PCBs) from these products can be ground into powder that absorbs toxic heavy metals in water.

The disposal of e-waste is an ever-increasing global concern in this rapidly changing technological era. About 20 to 50 million tons of e-waste is produced in the world each year. The two common conventional methods to treat this waste are either to incinerate or dump into landfills. Yet both methods create considerable environmental impact including giving off toxic gases in burning the plastic-metal mix in PCBs and the contamination of groundwater by the metals on the PCBs dissolving into the groundwater.

Although the metal parts of the PCBs have reuse value, the nonmetallic parts must be separated out from the PCBs for the metal parts to be recycled. Such separation process is costly considering that only the metal parts can be utilized while the nonmetallic parts (comprising 70% of the entire PCB) are to be disposed. Therefore, the investigation of potential applications for these nonmetallic parts of waste PCBs is an important area for research and practical application in industry.

To make the recycling of these waste resources more economical and to protect the environment from ecological contamination, the CBME team worked with a powder made by grinding the nonmetallic parts of PCB. They heated it and treated it with potassium hydroxide, a common technique to increase porosity in carbon-based adsorbents. The powder was added to solutions of copper, lead and zinc and these metals were removed.

With this method, favorable outcome of better metal removal efficiency has been achieved. It is observed that the metals adsorbed to the treated powder more efficiently than to three commonly used industrial adsorbents. The powder soaked up about 25% more copper than the same amount of commercially available ion-exchange resin did. The ground-up PCBs also had a higher adsorption capacity for these metals than several low-cost adsorbents, including soybean hulls and blast furnace slag. The study results demonstrated the high metal removal efficiency for a cost-effective novel adsorbent produced from an environmentally problematic e-waste.

According to Prof McKay, the team is now conducting a pilot study to make a 10kg batch of the adsorbent, and is discussing developing the project on an industrial scale with an e-waste recycling company in Hong Kong. He added that the ideal application for the new adsorbent would be to treat wastewater effluent from electronics producing companies, which would make a nice complete circle.

Related link: